Avoid unwanted engine cooling during port stay

Wednesday, December 13, 2023How to avoid unwanted cooling during port stay

Is cold sea water influencing your engine temperatures?

This article describes how the internal leakage rate from your thermostatic temperature control valves can influence your engine temperatures and how that can impact the engine performance.

COLD SEA WATER

leading to unwanted cooling of engines and auxiliary systems

Winter time in the northern hemisphere means cold sea water temperatures, which is being used for cooling of engines and auxiliary systems onboard many vessels.

These cold-water temperatures which in some areas can go down below 5° C (41°F), can influence the various cooling systems onboard, exposing the equipment for lower temperatures than they are designed for and risking expensive, repairs due to condensation forming when heated again and increased engine maintenance requirements.

The engine undercooling will normally occur during port stay, when engines and auxiliary systems are shut down.

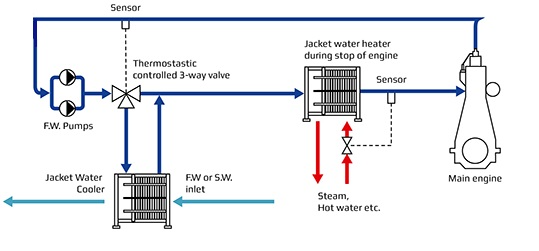

When engines and auxiliary systems are shut down, cooling is not needed, and the 3-way valve controlling the cooling circuit temperatures will close the port to the cooler side.

Due to the internal leakage rate of control valves, which typically is around 2-3% or higher, a certain flow of water will pass through the closed valve port, leading to unwanted cooling of these systems.

EXAMPLES OF VESSELS

with issues in cold waters due to internal leakage from the cooling valve:

Offshore Support Vessels (OSV): Temperature of auxiliary system drops below specified min. temperatures during port stay with the risk of condensation forming when system is starting up, wearing or breaking expensive equipment.

Tug boats: Pre-heater struggles to maintain high temperature of the engine during port stay. Longer engine warm up time required leading to extra fuel is burned before being able to leave port, leading to excessive fuel costs, and black smoke/exhaust from the smokestacks due to low engine temperature.

Ferries: Low temperature when pre-heater is running. Especially on ferries using electric heaters. Extra fuel burned for heating up the engines before leaving port.

4 stroke engines: Engine / auxiliary system which are cooled down during port stay, and does not allow for slow start, will be prone to rapid increase in engine temperatures when started, adding stress on mechanical components and seals.

Furthermore, fluctuating temperatures can be seen on engines with internal thermostats controlling the engine cooling. Low engine temperatures can cause internal pollution of engines, increasing need for service.

SOLUTION ON HOW TO AVOID ISSUES IN COLD WATERS

due to internal leakage from the cooling valve

The internal leakage rate of a cooling valve will in many cases be the cause of low temperature issues during port stay / anchorage in areas with cold water temperatures.

The internal leakage rate of a cooling valve will in many cases be the cause of low temperature issues during port stay / anchorage in areas with cold water temperatures.

The new Ultra-Low Leakage valve from BROEN Clorius Controls, has an internal leakage rate of less than 0,01% (ANSI Class IV), which will remove the unwanted cooling during port stay.

The new valve is designed to be the most compact 3-way valve in the market, and easy to retrofit no matter which valve brand is currently installed.

The valve is delivered with tailormade spacers, which fills in the gap between the valve and the flanges on the pipes and thereby no pipework to be done for the conversion, and possible to do by the crew directly.

For smaller sized vessels powered by 4 stroke engines where the cooling control valves are all integrated into the engine block, an optimal engine cooling control can be obtained by installing an Ultra Low Leakage valve before the water from the cooler is entering the engine.

If you have experienced some of the above issues or would like to know more about how our new Ultra Low Leakage rate can benefit your vessels, please don’t hesitate to contact BROEN Clorius Controls or one of our partners.

BROEN Clorius Controls cases

If you are looking for new ways to improve the fuel efficiency of your vessels, click to cases on how Clorius Controls have support various owners in their decarbonization efforts.

Download BROEN Clorius Controls Ultra Low Leakage brochure